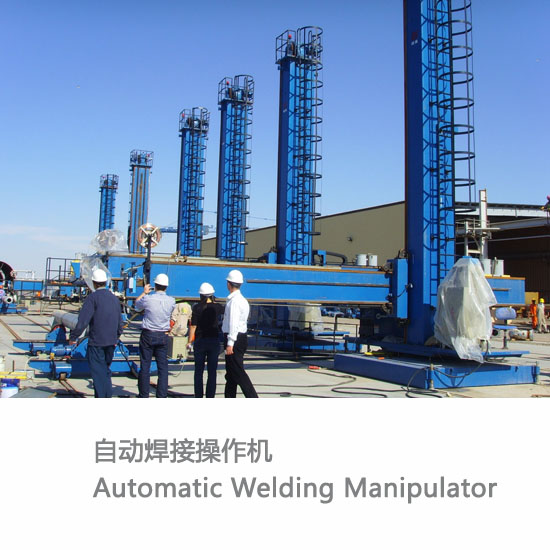

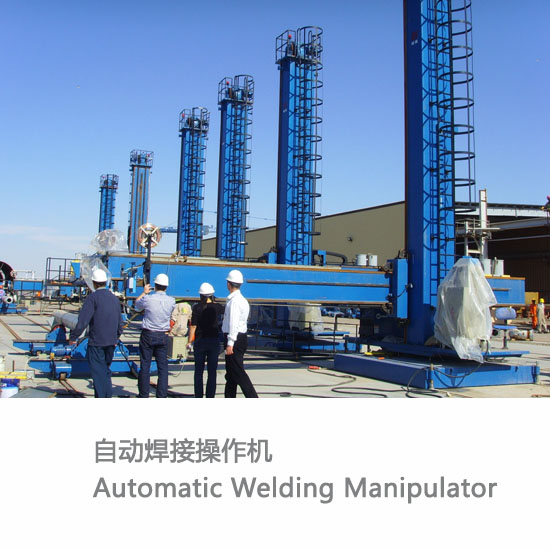

According to boom end load capacity, it is divided into light duty (LHQ), medium duty (LHZ), heavy duty (LHW) and super duty (HCJ);

Structural type: stationary type, moving type, stationary with rotation type and moving with rotation type;

Boom retraction sag 2mm/m; anti-fall device for boom elevation, safe and reliable;

Cross slider device at boom end, which can be adjusted by remote control box;

Guiding roller shaft is eccentric shaft, which can eliminate the clearance between roller and rail;

Column rotation: manual type or motorized type (optional); After rotating to the required position, there are manual type or pneumatic type locking device for customer's option.

Electric part consists of electric control box and remote control box. It has the interfaces for integrating control with welding positioner and/or welding turning roll, which can form the automatic welding center.

Main Technical Parameter:

|

Model

|

Light duty(LHQ)

|

Medium duty(LHZ)

|

Heavy duty(LHW)

|

Super duty(HCJ)

|

|

2×2

|

3×3

|

4×4

|

5×5

|

6×6

|

7×7

|

6×6

|

8×8

|

|

Effective elevation stroke(mm)

|

2000

|

3000

|

4000

|

5000

|

6000

|

7000

|

6000

|

7000

|

|

Effective retraction stroke(mm)

|

2000

|

3000

|

4000

|

5000

|

6000

|

7000

|

6000

|

7000

|

|

Elevation speed(mm/min)

|

1000

|

1650

|

|

Retraction speed(mm/min)

|

120-1200

|

50-1000

|

Min distance between boom lower

surface and rail surface(mm)

|

740(moving with rotation)

690(stationary with rotation)

|

1109(moving with rotation)

972(stationary with rotation)

|

1109(moving with rotation)

1090(stationary with rotation)

|

1226(moving with rotation)

1180(stationary with rotation)

|

|

Max allowable load of boom front end(kg)

|

80

|

120

|

200

|

600

|

400

|

|

Column rotation

|

manual rotation

|

±180°motorized or manual

|

|

Trolley moving speed(mm/min)

|

manual

|

1700

|

2500

|

2000

|

|

Trolley inner rail span(mm)

|

1000

|

1730

|

2000

|

2500

|